Design for repair: sustainability in product development

In modern product development, sustainability plays a crucial role. Following our successful case study on the PPG SprayMaster, we want to delve deeper into one of the core principles of sustainable product development: design for repair. This concept not only helps extend the lifespan of products but also reduces waste and promotes a circular economy.

What is design for repair?

Design for repair is a design methodology that creates products to be easily repairable. This means products can be easily disassembled, use standard components, and come with clear instructions for performing repairs. The goal is to give products a longer lifespan and enable consumers to carry out repairs themselves, reducing reliance on professional repair services and the need for replacements.

Principles of design for repair

- Modular design: A modular design means products consist of interchangeable modules that can be easily replaced or upgraded. This allows for the replacement of defective parts without discarding the entire product.

- Standard fasteners: Using standard screws and fasteners instead of unique or specialized parts allows users to easily remove and replace components with commonly available tools.

- Accessible components: Key components should be easily accessible without fully disassembling the product. This means designers need to consider the layout of internal components.

- Clear repair instructions: Providing detailed manuals and online tutorials helps users perform repairs themselves. This increases accessibility and confidence in the repair process.

Benefits of design for repair

- Environmental benefits: Designing products to be easily repairable significantly reduces waste. Fewer products end up in landfills, and there is less need for new raw materials to produce replacement products.

- Cost savings: For consumers, a product that is easy to repair means lower maintenance costs and a longer lifespan. This reduces the total cost of ownership and offers better value for money.

- Customer satisfaction: Products that are easy to repair lead to satisfied customers who are less likely to face the frustration of defective products that cannot be fixed.

- Support for the circular economy: Design for repair promotes the reuse of parts and materials, which is essential for a circular economy. This helps conserve natural resources and reduces the ecological footprint.

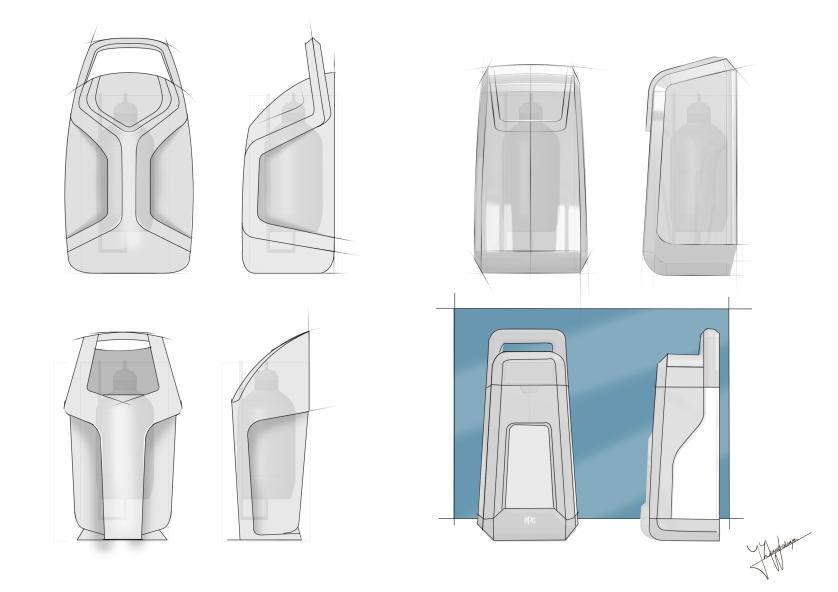

Example: PPG SprayMaster

The PPG SprayMaster, developed by TSG Group, is an excellent example of design for repair in action. The system uses standard screws and a modular design, making it easy to disassemble and repair. Key components are easily accessible, and clear instructions are available for maintenance and repair. This extends the product's lifespan and minimizes environmental impact. Learn more about this sustainable innovation.

Future Perspective

The future of product development lies in sustainable design methods like design for repair. By creating products that last longer and are easier to repair, companies can not only reduce their ecological footprint but also meet the growing consumer demand for sustainable and responsible products.

Design for repair & sustainability

Design for repair is a powerful tool in the fight for sustainability. It extends the lifespan of products, reduces waste, and promotes a circular economy. Companies that embrace this approach will not only contribute to a better environment but also enjoy satisfied customers and lower long-term costs.