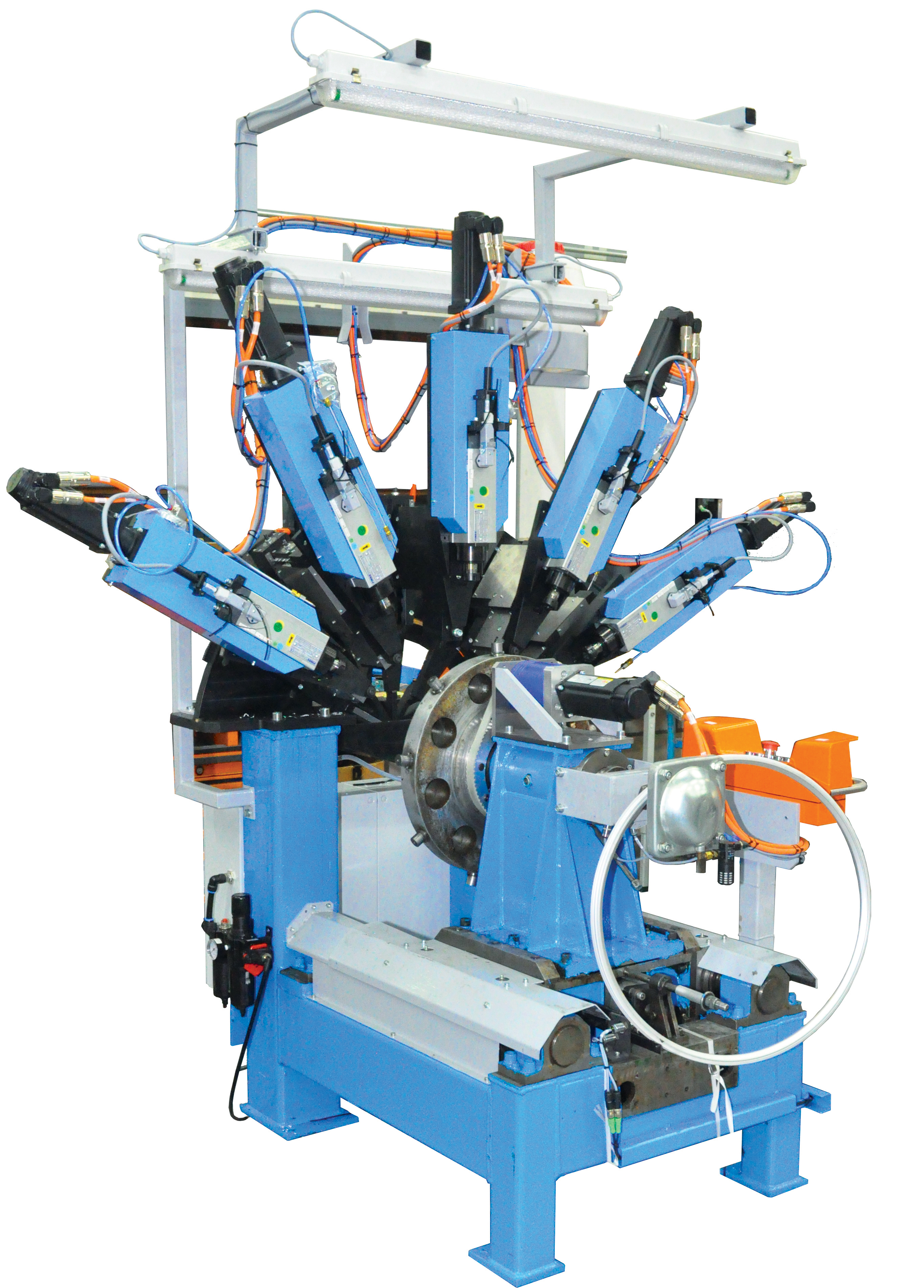

TSG InnoteQ has developed an industrial rim drilling machine for Ryde that makes hole patterns in metal bicycle rims.

Ryde is one of the leading manufacturers of aluminum rims. In 1908, Ryde was already known for its safety and first-class products.

From the very beginning, Ryde has been committed to the production of rims, an activity in which it has specialized since the 1950s. Over the years, Ryde has always worked with the largest bicycle and wheel manufacturers. This enables Ryde to supply the highest quality rims in every segment, from the simplest rims to the most advanced.

TSG InnoteQ has developed an industrial drilling machine for Ryde that makes hole patterns in aluminum bicycle rims. Production takes place in a one-piece-flow setup. This means that each specific rim is produced individually according to the principles of a mass production process.

Cycle time as well as accuracy and reproducibility are important requirements in the development of this 6-axis CNC-controlled machine. The associated controls and software were developed at TSG InnoteQ and the machine was fully realized in the proto/pilot shop of TSG Group.

Are you curious about how we can add value to your company?

Please feel free to contact us to discuss your ideas and wishes!